The cut grade is about how well a stone’s facets interact with light and is crucial to the diamond’s final beauty. Precise workmanship is required to prepare a diamond, so its proportions, symmetry and polish deliver a brilliant reflection of light.The better a diamond has been cut, the greater the diamond’s ability to reflect and refract light, as well as the brilliance of the diamond and the way it sparkles.

WHAT’S THE DIFFERENCE BETWEEN DIAMOND CUT AND DIAMOND SHAPE?

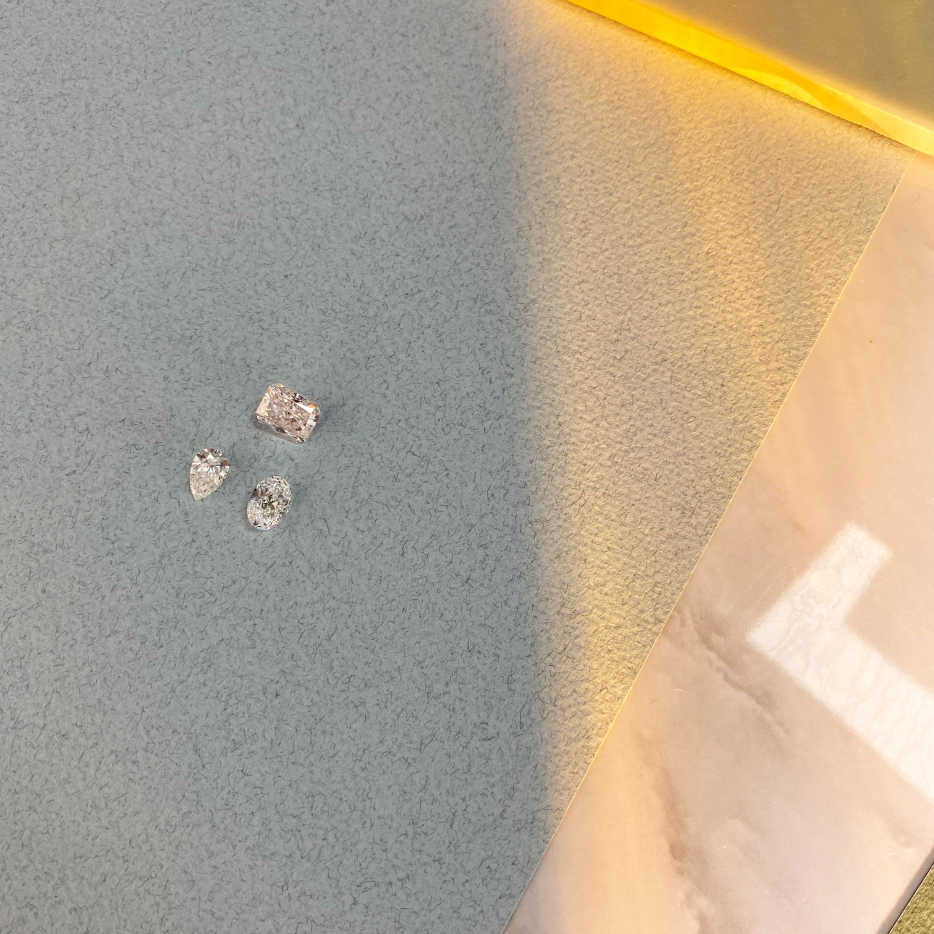

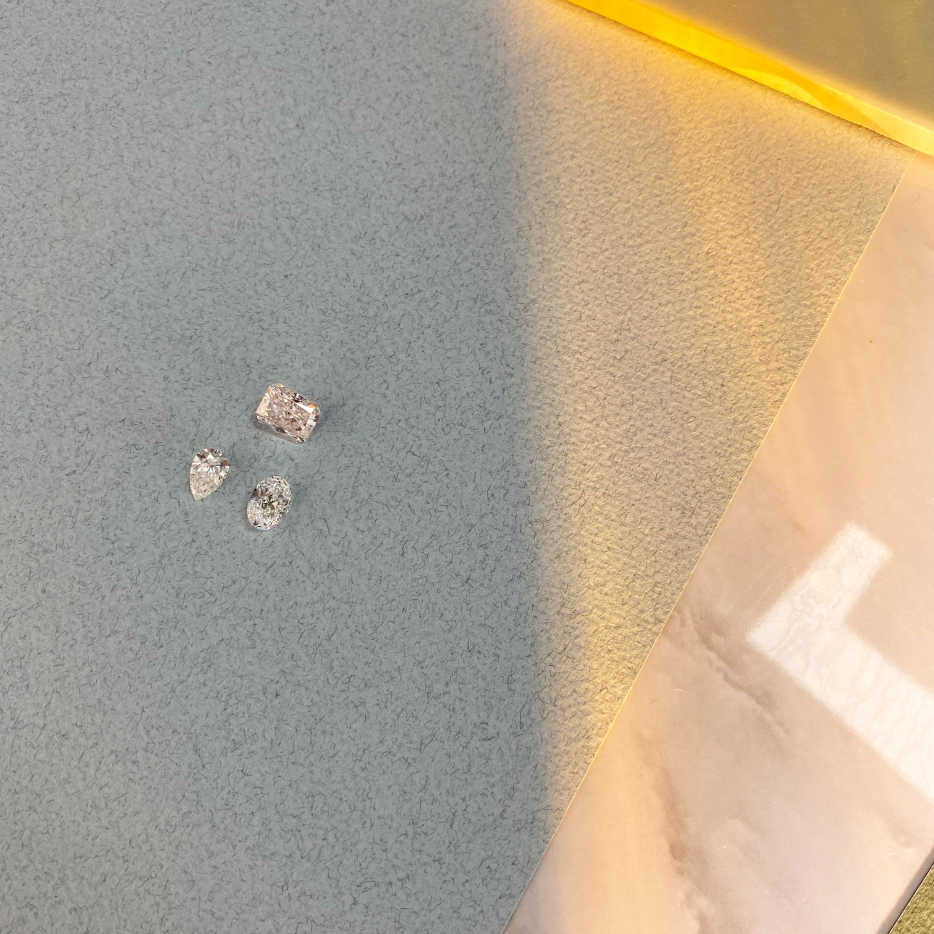

Diamond Cut and Diamond Shape are two very distinct things. Diamond Shape refers to the outline of the diamond, for example, Pear Shaped or Heart Shaped. Cut relates to the facets, symmetry, dimensions and reflective qualities of the diamond.

Key terms

Brilliance

Brilliance refers to the diamond’s white light return from its mirror-like facets – the foundation of a diamond's brightness and sparkle. The more facets, the more dazzling the light.

There are two facets inside a diamond. The physical facets are those cut into the stone that bounce light back towards the viewer like flashing lights, these flashes are the virtual facets. When light enters a diamond, the physical facets send it off in different directions and as the light angle changes, so do the way in which the set of facets interact and send the light back through the table, merging as brilliant light.

Fire

Diamonds slow down white light that enters into its table and scatter it into parts that display a shimmering spectrum of colour. This dispersive effect is known as fire. A high quality diamond will show flashes of every primary colour deep within the stone. Precision is necessary for the light to hit the perfect angle and fully disperse into a dazzling display of colour.

Scintillation

Known as the diamond's ‘sparkle’, scintillation is created by the interplay of flash scintillation (white light) and fire scintillation (multi-colored light). The facets split the white light into a spectrum of colours as it moves, contrasting against the darker areas. This symmetry creates the overall sparkle.

Pavilion depth

This is the distance from the bottom of the girdle (the dividing outer edge) to the culet (the pointed area where the facets of the diamond meet). A pavilion depth that’s too shallow or deep will allow light to escape from the side or leak out of the bottom, instead of through the crown.

HOW ARE DIAMONDS CUT?

A qualified diamond expert will cut a diamond with precision and skill. Diamond cutters follow an established set of angles and patterns to best accentuate a stone’s inner brilliance. A diamond’s ability to reflect light relies on three crucial factors; width, table and depth. Specifically, the way in which table size and depth relate to the diameter, have a significant impact on light return. The perfect width meanwhile, means that the light will hit the ideal refraction angle.

The cutting process has six parts:

Planning: the cutter analyses all the possibilities through the use of computer simulations – the Sarin Machine is often used to create accurate measurements and 3D models. This determines the best possible shape that will maximise its final quality and value, and minimise waste.

Marking: the rough diamond is marked using 3D laser technology after examining and measuring the dimensions under a magnifying glass. If flaws are made in the marking, this could cause huge changes to the final diamond.

Cleaving: a piece of rough diamond is split into separate pieces by either cleaving (using a tool like a hammer with a blade) or sawing (with lasers). The marked stone is placed on a spindle revolving at the speed of around 3000 rpm and lowered to the blade (layered with diamond powder as only diamond can cut the diamond). This gently taps the marked lines and cuts the stone.

Bruting: once the height and width measurements are determined by cleaving, the stone is then shaped along the girdle edge. This can be done through different methods, e.g. lasers or grinding it against another diamond on a high-speed machine called a lathe. This creates a rough griddle finish.

Polishing: this is the process of forming and shaping the facets to achieve the ideal amount of reflection and refraction of white light for a magnificent sparkle. There are two steps Blocking; the main 8 facets of the diamond are formed by placing a diamond into the tang (polishing base) and lowered on the scaife (polishing wheel infused with a mixture of olive oil and diamond dust) and Brillianteering; the final finishing that adds the alternating number of remaining facets.

Inspecting: the diamond is then thoroughly cleaned with acids and goes through the final inspection process, checking to see if it meets quality standards (shape, symmetry, cut, polish, etc).

After this the diamond is then sent off for assessment at a gemological laboratory.

HOW IS A DIAMOND GRADED?

A well-cut diamond should be proportioned so that light entering the gem exits back through the top of the stone, balancing the white light (brilliance) with flashes of colourful fire (dispersion). A diamond cut even just a few degrees out of proportion can emit light leakage from the bottom and results in dulled brilliance.

The GIA (Gemological Institute of America) looks for seven things when grading a diamond. These are brightness, dispersion, scintillation, weight ratio, durability, polish, and symmetry. Each factor is then assigned a grade under magnification, with the final grade based on the lowest assessment in any category. Symmetry and polish are exempt from this rule.

Diamond Cut Grade Chart

Excellent: nearly all the light is reflected through the table, providing the highest level of fire and brilliance

Very Good: a majority of light reflects through the table, offering a very good sparkle

Good: much of the light reflects through the table, showcasing some brilliance and sparkle

Fair: light exists through the bottom and sides, offering little brilliance

Poor: light escapes almost entirely from the sides and bottom, leaving almost no sparkle, brilliance or fire

HOW TO BUY BASED ON CUT

Do

Get an expert gemologist or diamond traders thoughts

Ask to see a high quality image of the diamond before you buy a fancy shaped diamond

Look at diamonds that display symmetry and have few dark area

Remember that diamond cut is what gives it the sparkle so don’t sacrifice on this for instance, a bigger stone

Don’t

Avoid diamonds that don’t carry a certificate from a reputable source like the GIA, HRD and IGI

Don’t consider diamonds that are too deep or shallow, they’ll leak light

Relevant Categories

Ring Guide

Looking to buy a new diamond ring, but not sure where to start? If you're unsure about the best place to be... Read More

Want to learn more about lab grown diamond?

Book an appointment with one of designers and discuss any questions you might have, or what your needs may be.