Toute notre collection

Tous les bijouxNos BestsellersPièces Personnaliséescarte cadeau digitaleAlliances Bague JackiePar Catégorie

Boucles d’oreillesColliersBraceletsBaguesEar cuffsBracelets pour HommesBagues de FiançaillesAlliances

Recycled gold has been having a moment. More and more fine jewelry brands today are deciding to use 18k recycled gold, instead of newly mined. By melting pre-loved pieces down, you can easily reshape gold without it losing its quality, whilst also cutting out the unsustainable mining process. Jewelry is actually one of the only products that can be completely recycled. 18k gold is the most popular choice for fine jewelry as it’s made from a combination of 75% pure gold and 25% alloy (other precious materials), meaning it’s as pure as possible whilst still maintaining its practicality.

When it comes to mining for gold, there’s no better place for it than trawling through old and disused jewelry boxes.

What is recycled gold?

Recycled gold is made from refined precious metals that are sourced from a combination of locations. According to the World Gold Council, recycled gold accounted for 28 percent of the total global gold supply of 4,633 metric tons in 2020. They found that 90 percent of that comes from discarded jewelry and the rest from electronic waste, like mobiles and laptops. Older cars with catalytic converters and electronics with circuit boards also contain recyclable gold and are sold to be melted down once they’re no longer in use.

The gold recycling method

Purity assessment

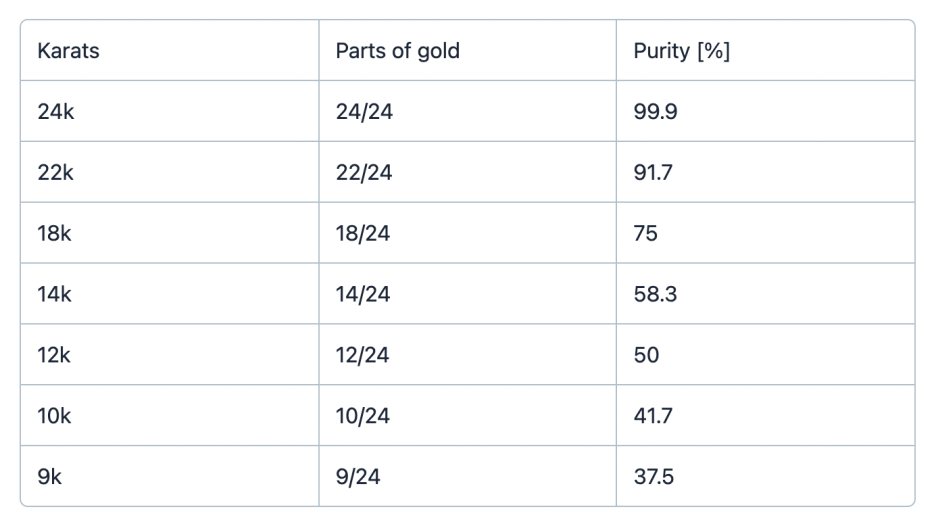

The process of recycling gold starts by assessing its purity. This is categorised using the karat system, ranging from 10K, 14K, 18K, 22K and 24K. 24 karat gold represents its purest form, meaning that 24 out of 24 parts of the metal are gold. This term may sound familiar to the carat measurement associated with diamonds, however this is a unit of mass used to weigh the material, whereas karat only measures the purity.

How are the quantities of impurities assessed? There are multiple methods:

An acid kit: the cheapest method, these kits come with a black touchstone and several acid solutions, which are marked for different karats. You start by scratching the touchstone with the gold in question, leaving a streak on the stone. Experts will then make a parallel control streak with a piece of gold of the same estimated value. Finally, they'll put a drop of an acid solution on both streaks and compare the reactions.

Electronic tester: a special liquid or gel makes it possible to create a circuit between the device’s probe and gold which then tests the gold’s electrical conductivity. This method is fairly accurate but must be fully cleaned of gel between uses.

X-ray fluorescence spectrometer: the most accurate test, these machines send X-rays through the tested item, exciting the atoms which move into a higher energy state. When they return to their ground state, they release radiation which the machine reads and can figure out what the item is made of.

Melting point test: 24k recycled gold has a melting point of 1,064 degrees Celsius, allowing you to differentiate between other materials.

Once the gold is sorted, it will be melted in a crucible and then poured into bars marked by purity or smelted to remove further impurities. The smelting process either burns impurities off or a flux, usually Manganese Dioxide, is added to react with impurities and separate them from the pure metal.

Alloying

Following the purity assessment process, gold used for jewelry is then usually alloyed (mixed with other metals) to produce a product with different desired properties. Most gold used in jewelry is alloyed with silver, copper and a little zinc to produce various shades of yellow gold or with nickel, copper and zinc to produce white gold. Rhodium is also added in to create white gold, creating a white lustre that also makes the surface much harder and scratch proof. Gold-titanium is also popular for wedding rings, introducing only 1% of titanium is enough to make it really strong and create a lovely grey toned shimmer.

Alloying can also alter its melting point, ductility and malleability. Reducing the high melting point of pure gold for instance, can save on energy costs. Adding platinum or nickel for can also increase the hardness of the alloy which is an advantage for jewelry as pure gold is too soft to work with and by hardening the surface it becomes scratch-resistant.

MINING

Mining gold is a long process that comes with an array of environmental and ethical concerns. It’s mined via four different methods:

Placer mining: the use of gravity and water to separate the dense gold from the other materials that surround it, retrieved by metal detecting, panning, cradling, sluicing and dredging.

Hard rock mining: using open pit or underground mining tunnels to retrieve the gold from the rock which is responsible for recovering most of the world's gold supply.

Product mining: gold is secondary, the main purpose of the mining operation is the recovery of other products like Copper, sand, gravel.

Processing gold ore: gold is extracted in a chemical process using mainly cyanide, from gold ore, finely crushed rock or earth.

To extract just 10g of gold, enormous conveyor systems need to move 5 tonnes of ore (a natural rock or sediment that contains valuable minerals). Not only does this emit greenhouse gases like diesel exhaust fumes into the atmosphere, but the mining process often involves the damming of rivers and felling of forests and water pollution.

RECYCLING

The majority of gold has actually already been mined and there are only a few mining regions left.

For over a decade, businesses in the jewelry industry have recognised the benefits of using recycled gold for more sustainable production. Recycling avoids the ethical and environmental concerns attributed to mining. Interestingly, it’s possible to recover nearly the same gold content from 40 scrap mobile phones than it is to mine a tonne of ore. Additionally, it can be melted down and recycled over and over again without losing its value or purity.

CHOOSING GOLD FOR JEWELRY

24K gold isn’t typically used in jewelry for a number of reasons. Firstly, it’s very expensive, containing twice as much gold as 14k, which means it also costs more to produce jewelry with. It does, consequently, have a higher resale value though. It’s also very soft and highly malleable, meaning it doesn’t retain shape well and scratches easily. It also has a bright, orange tone to it which isn’t deemed as attractive as the more creamy tone of gold most people are used to seeing. In the West, this isn’t typically used but tends to be more popular in China where it’s used in traditional wedding jewelry or collectible items

18k gold is made up of 75% gold and 25% alloy. 18k gold is the most typical type used for high quality fine jewelry and luxury watches. It has a desirable, sunny yellow appearance that is deemed classically attractive. Additionally as this gold has a high purity percentage, there is very little risk of skin irritation that can happen when gold is mixed with high quantities of nickel, for example. It is, however, expensive and fairly easy to scratch.

14k gold is the most popular for rings and other wearable jewelry in the US, UK and other Western countries. Being 14 out of 24 parts gold, it isn’t quite as bright or saturated as 18k but is cheaper and more durable. It does, however, have a larger potential to trigger skin irritation because of a higher alloy content.

Below this, 10k gold is the most impure it can be while remaining legally “gold” in most countries. Typically, luxury brands don’t offer 10k gold.It’s used in affordable, highstreet jewelry but is rare for engagement rings and fine jewelry.

Want to learn more about lab grown diamond?

Book an appointment with one of designers and discuss any questions you might have, or what your needs may be.