Toute notre collection

Tous les bijouxNos BestsellersPièces Personnaliséescarte cadeau digitaleAlliances Bague JackiePar Catégorie

Boucles d’oreillesColliersBraceletsBaguesEar cuffsBracelets pour HommesBagues de FiançaillesAlliancesHow Are Lab Grown Diamonds Made?

Lab grown diamonds are made by mimicking the mined diamond environment inside a lab. It’s important to highlight that ‘natural’ and lab grown diamonds are chemically and physically identical. Both diamonds are made from 100% carbon in a high pressure and high temperature environment, the environment being the only variable that differs between the two processes.

Today, lab grown diamonds can be made via multiple methods; namely, High Pressure-High Temperature (HPHT) and CVD (Chemical Vapor Deposition). The technology behind lab grown diamonds has made rapid advances in recent years, provoking growing competition with their mined counterparts. As this is a comparatively new process, it’s necessary to explain the creation process in more depth, avoiding the pitfalls of misinformation that can often circulate online.

A HISTORY OF LAB GROWN DIAMONDS

A quick contextual history lesson. In the early 1950s, an American physical chemist named Howard Tracy Hall started work at the General Electric Research Laboratory on codenamed "Project Superpressure". The team were focused on making a synthetic diamond for industrial applications and to reduce dependency on diamond miners. After four years of failed experiments, in 1954, Hall finally devised a plan to produce a diamond in a radical press of his own design. The correct material for the sample chamber and catalyst, as well as the required temperature and pressure were little more than guesses. He used iron sulfide and powdered carbon as the starting material, then tantalum disks to conduct the electricity into the cell for heat. This was conducted at about 100,000 atmospheres, 1600 °C and took 38 minutes. After breaking open the sample, clusters of diamond octahedral crystals were found on the tantalum metal disks. Voila, the first man-made diamond.

Since then, technology has progressed, allowing companies to grow higher quality diamonds more rapidly and more cheaply. Wuyi Wang, lead research scientist for the Gemological Institute of America, said that the market for synthetic diamonds was extremely competitive with multiple companies vying to improve their production techniques. According to a report commissioned by the Antwerp World Diamond Center (AWDC), today it costs $300 to $500 per carat to produce a CVD lab-grown diamond, compared with $4,000 per carat in 2008.

High Pressure-High Temperature (HPHT) refers to one of the two most common methods of producing a diamond. The second, CVD (Chemical Vapor Deposition), has been discovered more recently.

What is a lab grown diamond made of?

Carbon. Exactly like mined diamonds, lab grown are made of pure carbon with atoms that form in identical structures during the creation process. Even gemologists and diamond traders can’t tell the difference between lab grown and mined diamonds with the naked eye, it takes specialist magnifying equipment that looks at the structure of atoms to notice any differences and the accuracy is never guaranteed.

HOW ARE LAB GROWN DIAMONDS GROWN?

There are actually several ways to manufacture diamonds. Aside from the most common vapor-deposition approach, there is also the possibility to apply high pressures and temperatures, the detonation of explosives that create diamond nanocrystals and the use of ultrasound to create micron-size diamond crystals. Let’s take a look at the most popular methods.

HPHT (High Pressure High Temperature)

Developed during the 1950s, the HPHT method takes a small diamond seed and places it into a piece of pure graphite carbon. The carbon is pressurised to around 1.5 million pounds per square inch, using either a belt press, cubic press or a split-sphere press. If that wasn’t enough, the carbon is then exposed to scorching temperatures of over 1482°C. This pressure and heat begin to melt the carbon, forming a diamond around the initial seed, which is then carefully cooled.

Interestingly, HPHT can also be used on mined diamonds to enhance the stone’s colour, improving its grading. Most mined diamonds, for instance, have hints of yellow or brown. Not every diamond is suitable for this, if they have a low grade clarity they may crack or break during the treatment.

CVD (Chemical Vapor Deposition)

In 2015, a group of engineers and scientists, led by R. Martin Roscheisen (the founder of Nanosolar), developed an advanced approach to making diamonds. This involved the use of technology derived from making silicon chips and solar cells. With this, they made it possible to manufacture high-quality diamonds more quickly and cost-effectively than with existing technologies.

They called this new approach CVD (Chemical Vapor Deposition). CVD uses a small diamond seed (often actually an HPHT diamond) that’s placed inside a sealed chamber and heated to over 760°C. It’s then filled with carbon-rich gasses, typically methane and hydrogen, which are ionized into plasma using a technology similar to lasers or microwaves. This technology breaks down the molecular bond of the gas so that pure carbon can stick to the seed, forming a new diamond carbon atom by atom. Additional treatments like heat, irradiation or a Korean face mask may be used to enhance or change the diamond’s colour after it’s grown.

By modifying the shape and intensity of the plasma field, it’s been possible to make the reaction more efficient, creating pure diamond material of up to 150 times the rate at which the industry formerly produced it. According to Roscheisen, this process has made it possible to quickly manufacture large quantities of Type IIa diamonds, a pure white material that represents 1 to 2% of all natural diamonds.

The only reason scientific experts can determine that they are lab grown is because they resemble a type of diamond that appears rarely in nature, so seeing the diamonds in large quantities would be a giveaway.

Where are lab diamonds made?

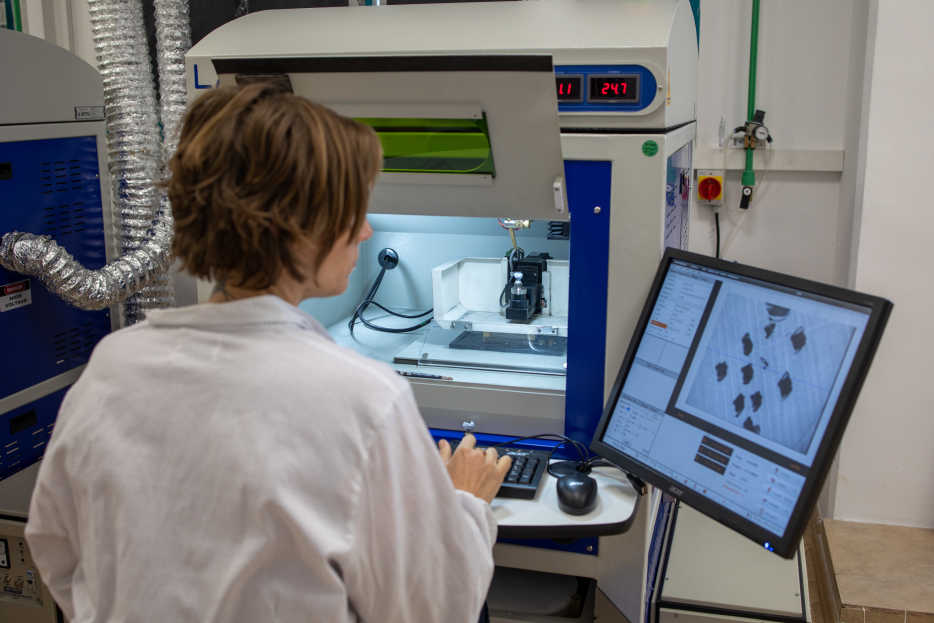

As you might expect, lab diamonds are made within… laboratories. Highly specialised, these are operated by skilled teams of scientists and engineers who use only the most cutting-edge technology. They can be found around the globe and unlike mines, are constantly improving in efficiency. Many, for instance, now produce and use solar energy to minimise their environmental impact as much as possible.

ARE LAB GROWN DIAMONDS REAL?

Absolutely. A lab-created diamond is a genuine diamond as it’s made from pure carbon, giving it identical physical and chemical properties to its mined counterpart. Fake diamonds are usually easy to spot, even to an untrained eye. They can include man-made pieces like cubic zirconia, synthetic moissanite and glass ‘diamonds’ or natural minerals such as zircon, white sapphire and spinel. These are usually softer and easily scratchable.

The FTC recently even changed the definition of a diamond by taking the word ‘natural’ out of it to include the lab grown variety. “[Lab-created diamonds] are not fakes. They’re not cubic zirconias. They have all the same physical and chemical properties of a mined diamond.” Stephen Morisseau, a spokesman for the Gemological Institute of America, stated. Labs, including the GIA, HRD and IGI are also now grading lab grown diamonds in exactly the same way as they do mined.

What are the benefits of growing a diamond in a lab?

SOCIAL IMPACT

Growing diamonds in a lab means you have total control over the entire process, from creation to consumer. It avoids untraceable exchanges with shady middlemen, creating a completely transparent supply chain. For instance, mined diamonds are often sourced from complex, untraceable and unethical supply chains from conflict regions and are associated with community displacement, poor working conditions, low wages, human rights violations and child labour.

ENVIRONMENTAL IMPACT

Lab grown diamonds are without a doubt less harmful to the environment and its surrounding communities. Laboratories take up comparatively very little space, whereas miners are having to dig deeper into the earth which is leaving enormous craters in the ground. It can take an entire factor more energy to extract an underground diamond from Earth than it takes to create one above ground.

In a study run by Frost & Sullivan, it is said that diamond-growing facilities “are often located in areas that have a negligible impact on the environment and have almost no impact on biodiversity in the area of operation.” On average they disrupt just 0.07 square feet of land per carat and only 1 pound of mineral waste.

QUALITY & AFFORDABILITY

The creation of a lab diamond is more efficient and cost-effective than the mining process. Each diamond is unique and the quality is based on how it performs on each of the 4Cs. As the processes of creating lab grown diamonds continue to improve, the difference in price grows, with lab grown diamonds currently up to 50-60% less expensive than mined diamonds of the same quality.

WHY LAB GROWN DIAMONDS?

When we consider lab grown vs mined diamonds, the social, environmental and economic differences in production are stark.

Unlike in diamond labs, there is very little control over the mining process, from creation to how many hands it exchanges until it reaches your finger. Scientists don’t even know how long it takes for a mined diamond to form as it’s often not a continuous process, being easily interrupted by a shift in temperature or pressure. After carbon dioxide is exposed to extreme temperatures and extreme pressure, it’s moved from the earth’s core to its crust through Kimberlite Pipes, a type of igneous rock which formed from cooled volcanic activity. This can take around 1 to 3 billion years. Then, typically diamonds are mined via two methods; open pit, which maintains exposure to the surface throughout the extraction process and underground, where an entry is made through a horizontal or vertical tunnel. Heavy duty machinery and explosives are then used to clear away the debris.

Labs take up limited space in comparison to the vast expanse of excavated mining land, but ethically also avoid community displacement and provide safe working conditions with good pay. This is opposed to the dangerous mining environments, mistreatment of workers and child labour often attributed to the sourcing of ‘natural’ diamonds.

Catégories pertinentes

Diamond Buying Guide

Choosing the right diamond is an important task, particularly if that diamond is one that will be worn all ... En savoir plus

Ring Guide

Looking to buy a new diamond ring, but not sure where to start? If you're unsure about the best place to be... En savoir plus

Want to learn more about lab grown diamond?

Book an appointment with one of designers and discuss any questions you might have, or what your needs may be.